Over the last 20 years, China’s inverter charger sector has changed completely. It started with simple off-grid inverters. Now Chinese factories produce sophisticated all-in-one hybrid units. These devices combine inverter, battery charger, and solar MPPT controller in one box.

The International Energy Agency (IEA) says China made over 70% of the world’s solar panels and more than 40% of global battery storage systems in 2023. The same strength shows in hybrid inverter chargers. Strong government support and fast factory growth drive this success.

Policies like “Made in China 2025” and big renewable energy goals helped a lot. China built a complete supply chain. Exports now go to Europe, Africa, and Southeast Asia in huge numbers.

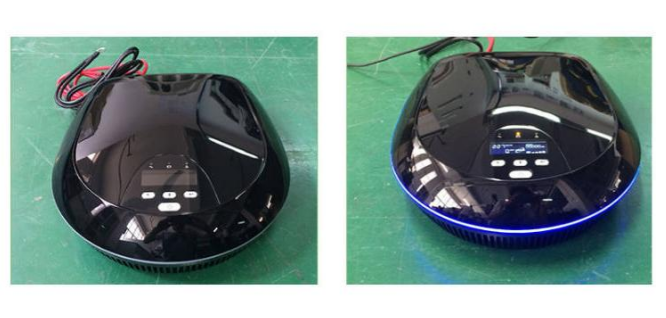

Chinese inverter technology has improved quickly. Old models only changed DC to AC for off-grid use. Today’s units, such as the PVG and PVM Plus series, do everything in one device.

The PVG series has a built-in MPPT solar charger. It gets the most power from panels and charges batteries properly. It can even work without batteries connected.

New models reach over 99% efficiency. They use silicon carbide (SiC) and gallium nitride (GaN) parts. Many now include smart load management and AI features.

Chinese brands also pair inverters with lithium batteries. These batteries last up to 3,500 cycles — five times longer than old lead-acid ones. Most units connect to Wi-Fi or RS232. Owners can watch and control them from phones.

Top companies file many new patents each year. Heavy spending on research keeps them ahead in performance and reliability.

l Price per kW: Chinese products cost 40-60% less than European or American ones.

l Top efficiency: By 2025, many models exceed 98%. They often beat Western brands.

l Failure rate: Better quality control keeps problems under 1.2%.

l New models: Big factories release fresh designs every 12-18 months.

That is why “china inverter charger manufacturer” is still the top search for buyers who want both low price and modern features.

l Full control of the supply chain: They make cells, BMS, and inverters themselves. This lowers cost and improves matching.

l 40-60% cheaper production than EU/US brands because of scale and local parts.

l All major certificates come standard: ISO9001, ISO14001, CE, UL, ETL, CCC, Thayer, etc.

l Quick custom work and OEM/ODM service for private-label needs.

l Strong worldwide shipping and after-sales support in Europe, Africa, and the Americas.

l Modern R&D labs and skilled teams keep products new and stable.

l English-speaking engineers give fast help, remote checks, and training.

l Free lifetime firmware updates and phone apps for monitoring.

Fortune Business Insights predicts the market will pass USD 25 billion by 2030. Yearly growth will stay above 7%. People use them for:

· Remote houses and cabins

· RVs and boats

· Telecom towers

· Village mini-grids in Africa

· Home backup power in Europe

Pure sine wave models have replaced modified sine wave almost everywhere. Pure sine wave units run appliances better and make equipment last longer.

Many leading factories now aim for carbon-neutral production. They join RE100 and use recycled aluminum and greener circuit boards.

Next features include two-way charging (vehicle-to-grid), zero-export limits, and virtual power plant support.

Chinese suppliers also help overseas partners meet ESG rules with full life-cycle reports and eco-friendly packing.

Follow these simple steps:

1. Ask for recent factory audit reports and ISO certificates.

2. Check bank references or use trade assurance services.

3. Make sure minimum order quantities are flexible for test runs.

4. Confirm they have English-speaking staff.

5. Ask how long custom design takes.

6. Look for extra benefits like free firmware updates, remote monitoring, longer warranties, and training visits.

Companies like ZLPOWER show all these strengths. We focus on high quality, good service, and aim to become a respected global power brand.

|

Feature |

Pure Sine Wave Inverter |

Modified Sine Wave Inverter |

|

Waveform Quality |

Clean, smooth sine wave |

Stepped approximation |

|

Equipment Compatibility |

100% (including sensitive gear) |

Limited |

|

Efficiency |

High (90–95%) |

Moderate |

|

Noise & Heat Generation |

Minimal |

Higher |

|

Cost |

Higher upfront |

Lower upfront |

|

Best Use Case |

Industrial, medical, telecom |

Basic lighting, resistive loads |

People still argue about low-frequency vs high-frequency pure sine wave inverter designs. Low-frequency units handle big surges and last longer. High-frequency ones are lighter and more efficient.

Real examples prove their worth:

· Australian remote farms run GSII systems through storms without problems.

· Solar-powered clinics in Africa depend on pure sine wave models for medical machines.

Experts expect another 10-15% price drop by 2027. New units will add cloud energy tracking. Inverter chargers will become the heart of energy independence everywhere.

A: They offer 40-60% lower prices, efficiency above 98%, full CE/UL/TUV certificates, and fast custom work — the best mix of cost and quality.

A: Yes. Top factories keep failure rates below 1.2%, use pure sine wave output, and carry ISO 9001, CE, UL1741, and ETL marks. They work well even in tough conditions.

A: Definitely. Good factories provide private labeling, custom software, special voltage or phase options, and your own app — usually ready in 4-8 weeks from design to sample.